The Original Inventors of Conformal Coating Technology

Conformal coatings are a breathable, protective layer that will protect against any environment the PCA is exposed to by filtering out the airborne contaminants and maintaining long-term surface insulation resistance while allowing any moisture trapped in the circuit board to escape.

Conformal Coatings protect against all major threats to a PCB's integrity:

Conformal Coatings protect against all major threats to a PCB's integrity:

Thermal shock, cycling

Mechanical shock (vibrations)

Water intrusion, corrosion

Foreign matter damage: dust, gravel, sand

ThermoSink 35-7

ThermoSink thermal gels and encapsulants excel at thermal management. They offer flexibility in formulation, allowing for customization of flow properties and cure rates to meet specific needs.

Available in soft gel or firm elastomer forms, they ensure long-term stability during thermal cycling. ThermoSink can be used as a thermal interface material or for encapsulating entire assemblies.

The two-component 1:1 mix ratio packaging simplifies automated dispensing processes. With excellent adhesion to diverse substrates and resistance to harsh environments, ThermoSink products are ideal for consumer and industrial applications requiring reliable thermal performance.

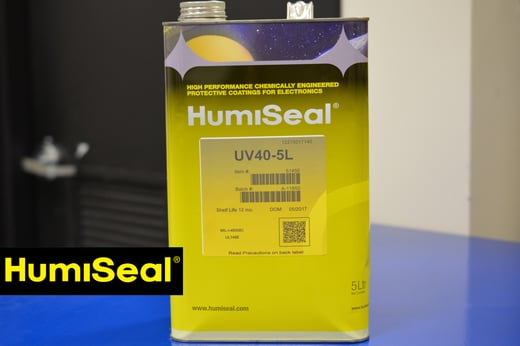

UV550

HumiSeal® UV550 is a solvent-free, UV-curable elastomeric acrylate conformal coating offering enhanced flexibility compared to other UV-curable coatings.

Designed to endure over 1000 thermal shock cycles in high-thickness component areas, it maintains stable SIR characteristics for 1000+ hours. Curing options include LED, Arc, or Microwave systems.

This coating boasts exceptional flexibility, moisture resistance, electrical insulation, and chemical properties. It withstands 1000 thermal shock cycles, fluoresces under UV light for precise application, features a secondary cure mechanism, resists yellowing, and is silicone-free. Compliant with RoHS standards.

Sharp Edge Coverage

Conformal coating technology faces significant challenges in keeping pace with the rapid advancements in PCB technology. As circuit boards become increasingly compact, with tighter component spacing and more delicate parts, traditional conformal coatings often struggle to spread evenly due to fluid dynamics. This inconsistency can jeopardize the reliability of electronic devices.

HumiSeal's Sharp Edge Coverage represents a breakthrough in conformal coating science, enabling the application of a consistent layer of material, even on the most densely packed circuit boards. By addressing these challenges, Humiseal ensures enhanced protection and reliability for modern electronics.

Main Benefits Conformal Coatings

- Insulating property allow a reduction in PCB conductor spacing of over 80%

- Can help eliminate the need for complex, sophisticated enclosures

- Lightweight

- Completely protect the assembly against chemical and corrosive attack

- Eliminate potential performance degradation due to environmental hazards

- Minimize environmental stress on a PCB assembly

- Inherent flexibility conforms to varied component profiles

Applications for Conformal Coatings

-

Automotive PCBs

-

Appliance/White Goods PCBs

-

EV Charging or Automotive Batteries

-

Aerospace

Talk to an Expert

Click the button below to talk to an expert in conformal coatings

HumiSeal is a wholly owned brand of Chase Corporation. To learn more, visit www.chasecorp.com